Executive

Summary

This

project is collaboration between the Department of Mechanical and Materials UKM

and the Department of Water of Irrigation. The latter observed high maintenance

costs due to damages to pumps as results of damages by instability of water

entering the pump. Anti-vortex device (AVD) is a device designed to suppress

vortices that exist in pump sump. The existence of vortex is not desired

because it causes the flow to approach the pump impeller blade at an angle

which can lead to vibration to the pump and cavitation inception on the surface

of impeller blade. Vortices that occur in a pump sump could take place either

on the surface, which is called surface vortex, or at the wall boundaries of

the sump, namely submerged vortex. In this project experimental approaches

including the use of measuring equipment such as swirl meter and photographic

devices such as high speed cameras are used to capture flow structures produced

by the newly designed plate type floor splitter which could suppress submerged

vortices originated from the geometries of a sump. Prior to undertaking the

experimental works, the design of plate type floor splitter of a transfer pump

equivalent to an industrial use are properly prepared. Both stress and strain

analysis as well as fluid dynamics analysis will have to be completed using

existing commercial-type modelling software. A properly designed sump and

impeller with this vortex suppresser avoids damage to the pump therefore

minimize maintenance fees and at the same time avoid potentially catastrophic

damages to connected water infrastructure= and the system it supports due to

damaged pumps. This project benefits the designing and the maintenance

department catering for large amount of water transfer projects such as

the storm water management group,

large-scale water supply for agriculture or water transfer projects.

Description

The aim of

the study is to determine the optimal design of plate used as floor splitter to

effectively reduce submerged vortices in pump intake by experimental and

numerical approach. Therefore, the research methods that will be used to

accomplish the goal of this study are summarized as follows: Numerical

modelling and calculation The pre-determined test subjects will be constructed

virtually by means of numerical modelling and the predicted flow pattern will

be established with the aid of CFD software. The constructed test models will

follow the dimensions and environment of the actual experimental setup to

ensure accuracy of the predicted results. Experimental measurement After

obtaining results from the CFD simulation, the data will be studied and shapes

that are possible to be manufactured as prototypes will be selected and prepared

for the experimental stage of the study. At the same time, the experimental

setup consists of pump intake sump, axial flow pump, flow circulation pipe and flow

regulator will be prepared. The use of PIV will be incorporated to capture the

actual velocity profile of the selected shape

along with

the vorticity at the pump intake. Data analysis Images that are captured with

the PIV equipment will be processed using special software into analyzable

figures. The two dimensional flow field acquired from the measurement will be integrated

to create a three dimensional field. Scope of study and theoretical framework

The scope of the study focuses on splitter type AVD in the form of a plate. The

modification of the plate is not restricted to the geometric shape only but also

to other design variables such as the orientation and profile of the plate. The

type of vortex to be evaluated is submerged vortex, which can arise from floor,

back wall and side wall of the pump sump. The velocity profiles which determine

the vorticity of the flow, are to be captured in the area of pump intake

directly below the pump suction bell. Independent and dependent variables are

outlined at the preliminary stage of the study to build up a theoretical

framework which plays an important role in guiding the entire process of the

research study.

Progress

|

|

|

|

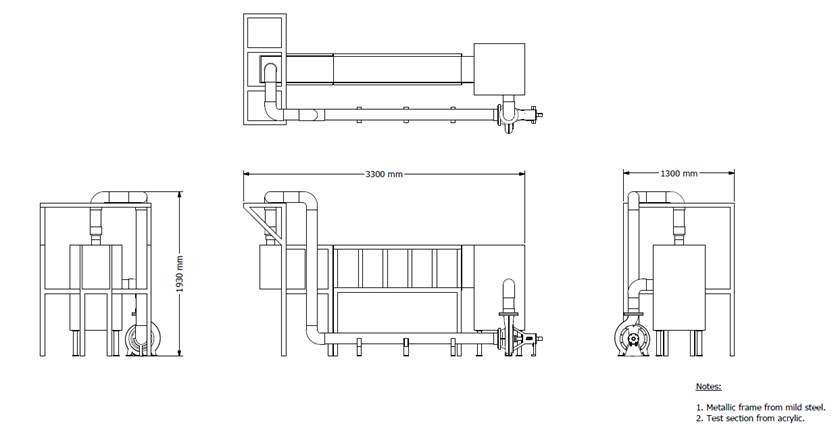

Drawings

of the newly built channel flow |

|

|

|

|

|

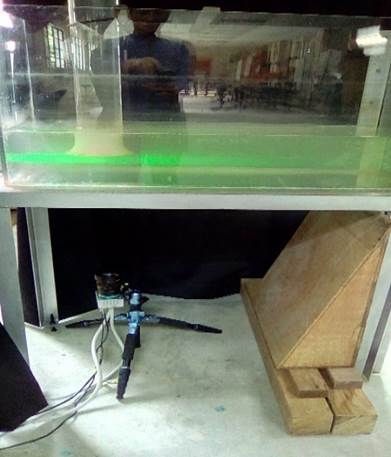

Building

the channel flow |

Channel

flow ready for pump and pipe |

|

|

|

|

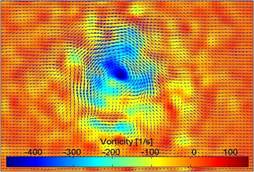

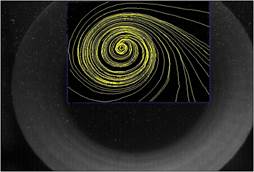

The submegred vortex appear during pump operation |

PIV |

|

|

|

|

PIV images |

Contours |

[Back]